Introduction:

At Saltech, we take pride in partnering with industry pioneers like Anest Iwata. As the first developers of oil-free scroll compressors, Anest Iwata has revolutionized the compressor industry with their innovative technology and commitment to excellence. Let’s delve into the journey of how Anest Iwata became the trailblazers in this field.

The Vision and Early Challenges

In 1986, Anest Iwata embarked on a groundbreaking journey to develop an oil-free compressor. At that time, oil-free compressors were not the first choice for industrial applications due to their higher price, limited functionality, and shorter service life. However, Anest Iwata was determined to stand out from the competition by creating a product that was quiet, low vibration, and compact. The decision to pursue the scroll mechanism was driven by its potential to meet these criteria.

The Scroll Development Project Team

Mr. Sato Kazuaki, an engineer in Anest Iwata’s Advanced Technology Laboratory, was part of the original scroll development project team. Reflecting on the project’s inception, he shares, “We wanted our product to offer something different. The scroll pump provided more possibilities than any other pump in use at the time.”

Overcoming Technical Hurdles

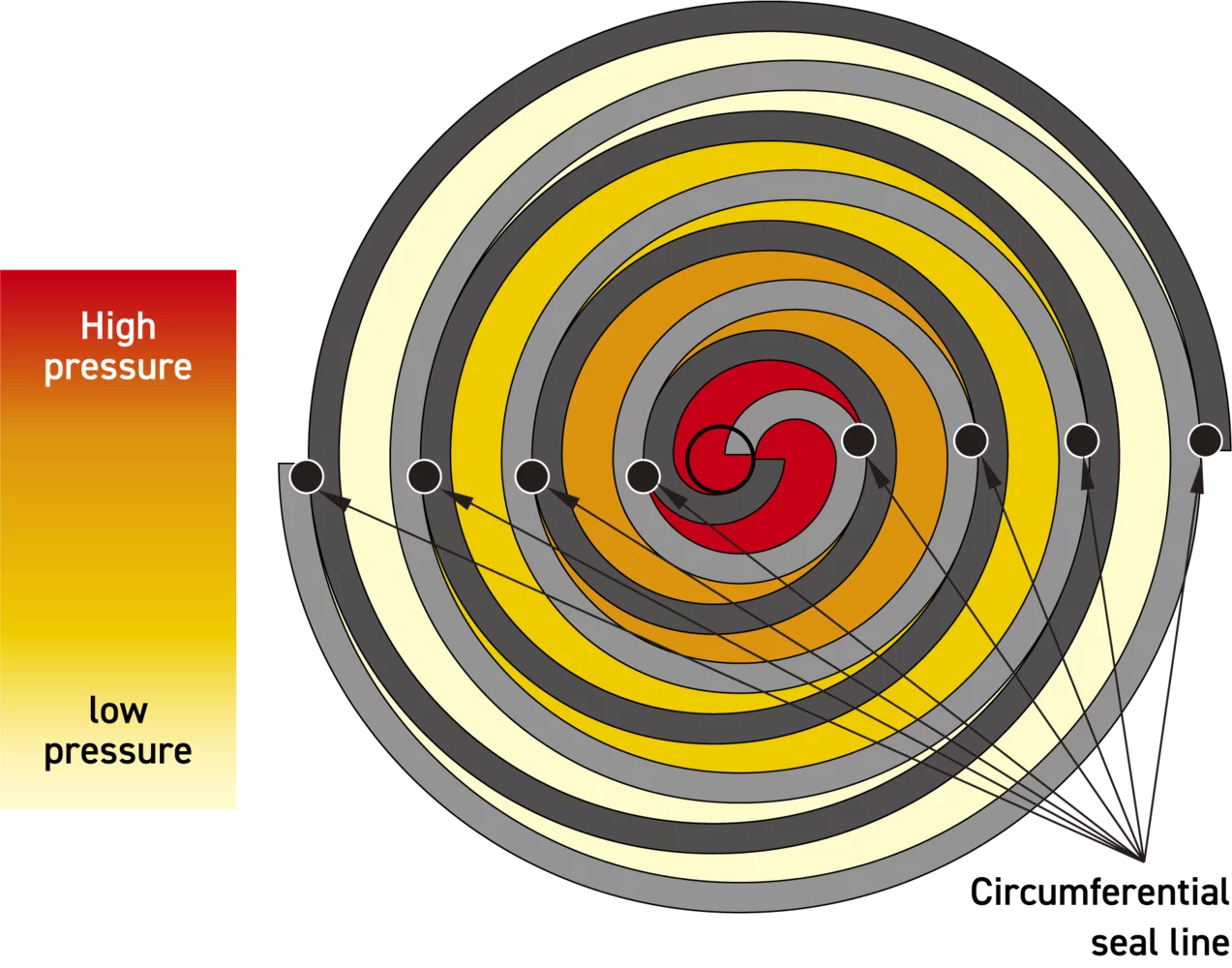

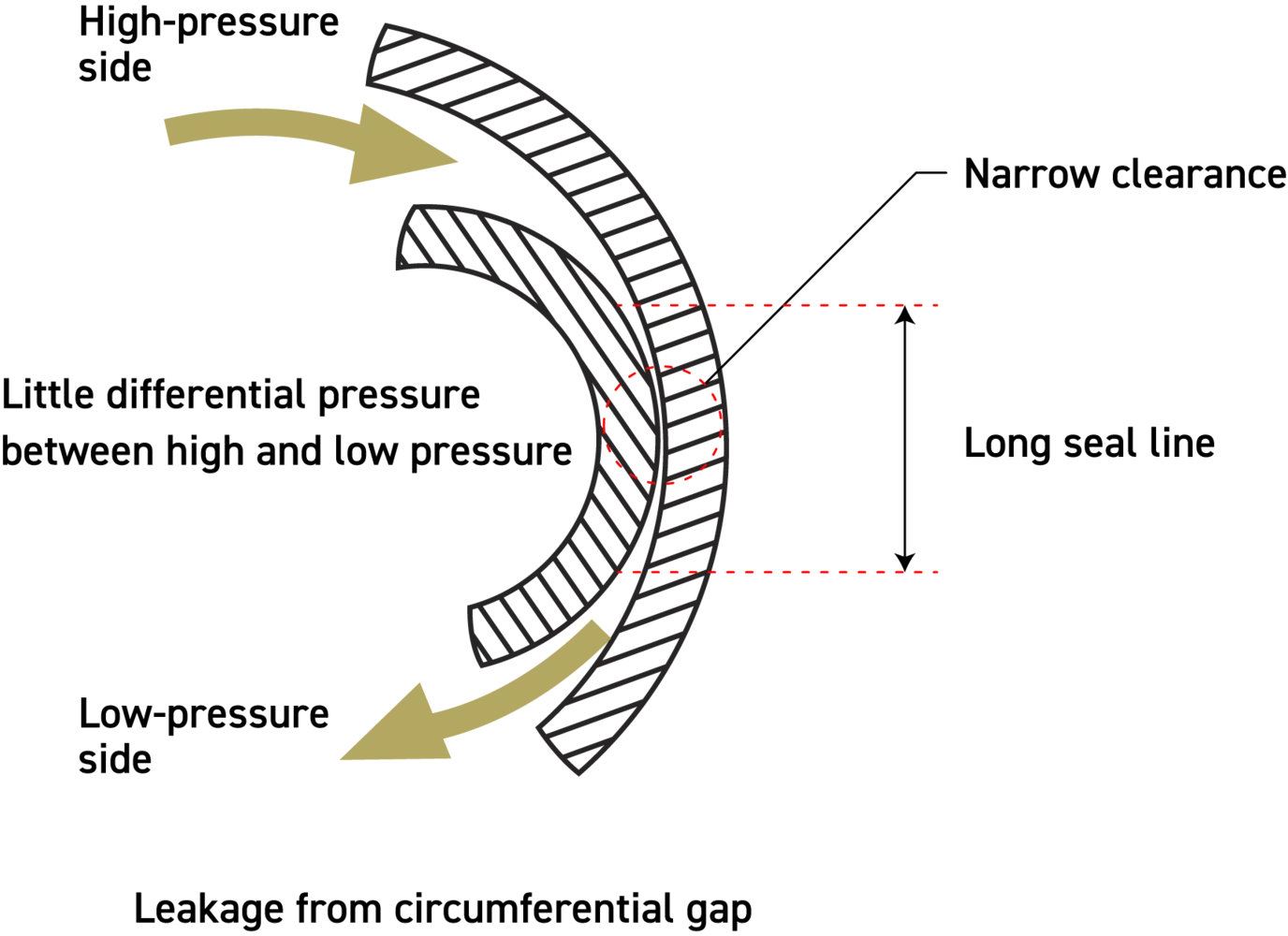

The development of the scroll pump was fraught with challenges. One significant hurdle was creating the unique circular motion required by the spiral mechanism, which was considered unachievable for an oil-free machine. Anest Iwata overcame this by inventing the world’s first precision crankpin mechanism and adjusting the clearance of the spirals.

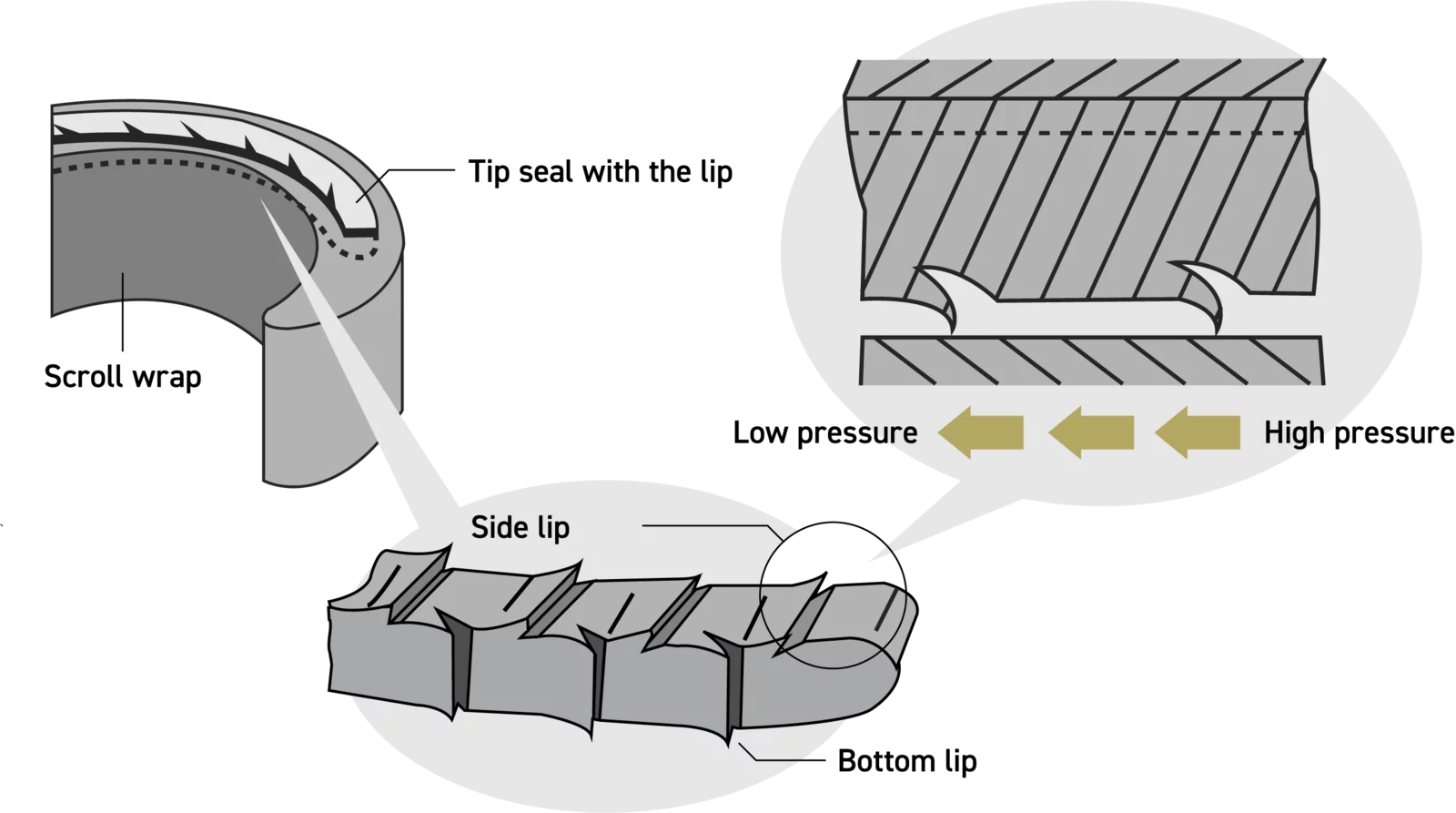

Another major challenge was developing effective tip seals to trap pressurized air without the aid of oil. The team experimented with various materials and designs, eventually developing the innovative “lip” design, which drastically improved the sealing effect and compression efficiency. This breakthrough, along with rigorous durability testing, resulted in seals that could withstand 10,000 hours of operation.

Achieving Success

Despite numerous obstacles, including stringent deadlines, the project team persisted. After extending the project timeline and conducting extensive evaluations, Anest Iwata successfully launched the world’s first oil-free scroll compressor. The product’s reliability and efficiency earned the trust of customers, proving its value in the market.

The Impact of Oil-Free Scroll Compressors

Anest Iwata’s oil-free scroll compressors offer several advantages:

- Environmentally Friendly: By eliminating the need for oil, these compressors reduce environmental contamination.

- Reduced Maintenance: With fewer moving parts and no oil, maintenance costs and downtime are significantly reduced.

- Clean Air Output: Essential for industries like healthcare and food processing, oil-free compressors provide high-purity air.

- Energy Efficiency: Designed for optimal performance, these compressors operate efficiently, saving energy and costs.

Explore Our Range

At Saltech, we are proud to offer a comprehensive range of Anest Iwata compressors, including oil-free, reciprocating, and rotary screw compressors. Visit our website to explore our offerings and find the perfect solution for your industrial needs: Saltech Compressors.

For inquiries, please contact us at info@saltech.ltd. Let’s power up your operations with the best in class!

References: Content based on Anest Iwata’s industry studies and internal project reports.